Txais siv cov cuab yeej tshiab thiab siv tau zoo tshaj plaws, kev txhim kho cov khoom siv automation, tshwj xeeb tshaj yog cov ntawv thovmuaj neeg hlauautomation thev naus laus zis, yog qhov ntsuas tseem ceeb rau kev lag luam casting los siv kev txhim kho kom ruaj khov.

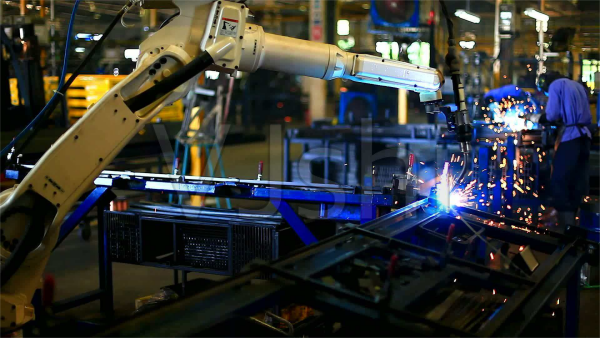

Hauv kev tsim khoom casting,industrial robotstuaj yeem tsis tsuas yog hloov cov neeg ua haujlwm kub, muaj kuab paug thiab qhov chaw txaus ntshai, tab sis kuj tseem txhim kho kev ua haujlwm, txhim kho cov khoom precision thiab zoo, txo cov nqi, txo cov khoom pov tseg, thiab tau txais cov txheej txheem tsim khoom siv tau yooj yim thiab siv tau ntev. Cov organic ua ke ntawm cov khoom siv casting thiabindustrial robotstau npog ntau yam xws li tuag casting, nqus casting, low-pressure casting thiab xuab zeb casting, feem ntau yog cov tub ntxhais ua, casting, tu, machining, tshuaj xyuas, kev kho deg, kev thauj mus los thiab palletizing.

Lub rooj cob qhia qhov chaw tsim khoom tshwj xeeb yog qhov tseem ceeb, tag nrho ntawm qhov kub thiab txias, plua plav, suab nrov, thiab lwm yam, thiab qhov chaw ua haujlwm yog qhov hnyav heev. Cov neeg hlau muaj peev xwm siv tau rau lub ntiajteb txawj nqus casting, low-pressure casting, high-pressure casting, spin casting, covering workshops with different casting method of black and non-ferrous casting, greatly reduce the zog siv cov neeg ua haujlwm.

Raws li cov yam ntxwv ntawm castings, industrial robot gravity casting automation units muaj ntau hom layout.

(1) Lub voj voog yog tsim rau castings nrog ntau yam specifications, yooj yim casting, thiab cov khoom me me. Txhua lub tshuab nqus hlau tuaj yeem nrum cov khoom sib txawv, thiab cov txheej txheem sib dhos tuaj yeem muaj ntau haiv neeg. Ib tug neeg tuaj yeem ua haujlwm tau ob lub tshuab nqus tsev. Vim muaj qee qhov kev txwv, nws yog hom siv ntau tshaj plaws tam sim no.

(2) Hom symmetrical yog tsim rau castings nrog cov khoom tsim, xuab zeb cores, thiab complex casting txheej txheem. Raws li qhov loj ntawm cov castings, me me castings siv cov tshuab me me inclined gravity. Cov chaw nres nkoj nchuav yog tag nrho nyob rau hauv lub voj voog ncig ntawm cov neeg hlau ua lag luam, thiab cov neeg hlau ua lag luam tsis txav mus los. Rau cov castings loj, vim hais tias cov cav tov inclined lub ntiajteb txawj nqus yog loj, cov neeg hlau muaj yuav tsum tau nruab nrog ib tug txav axis rau pouring. Hauv hom no, cov khoom lag luam casting tuaj yeem muaj ntau haiv neeg thiab cov txheej txheem sib dhos tuaj yeem ua tsis tiav.

(3) Qhov tsis zoo ntawm sab-los-sab ncig thiab symmetrical hom yog tias cov logistics ntawm cov xuab zeb cores sab sauv thiab cov casting qis yog ib qho chaw nres tsheb thiab kuj tawg, thiab kev siv lub tshuab nqus tsev ib sab los daws qhov teeb meem no. Tus naj npawb ntawm lub ntiajteb txawj nqus tshuab yog teem raws li qhov luaj li cas ntawm cov castings thiab cov txheej txheem atherosclerosis, thiab industrial robots yog tsim los txiav txim seb nws puas yuav tsum tau tsiv. Kev pabcuam grippers tuaj yeem tsim kho kom tiav cov haujlwm ntawm cov xuab zeb core tso thiab casting unloading, ua tiav qib siab ntawm automation.

(4) Lub voj voog hom Kev nrawm nrawm ntawm hom no yog qhov ua tau zoo dua li cov qauv dhau los. Lub ntiajteb txawj nqus tshuab tig rau ntawm lub platform, nrog rau cov chaw tso dej, qhov chaw txias txias, chaw nres tsheb thauj khoom, thiab lwm yam. Ntau lub tshuab nqus hlau ua haujlwm ib txhij ntawm cov chaw sib txawv. Lub pouring neeg hlau tsis tu ncua siv txhuas cov kua rau pouring ntawm qhov chaw nres tsheb pouring, thiab lub picking neeg hlau yog unloading synchronously (nws kuj yuav ua tau manually, tab sis vim nws high efficiency, kev siv ntawm kev ua hauj lwm yog siab dhau lawm). Hom no tsuas yog tsim nyog rau kev tsim ib txhij ntawm castings nrog cov khoom zoo sib xws, cov khoom loj, thiab cov neeg ntaus sib xws.

Piv nrog rau lub ntiajteb txawj nqus casting tshuab, lub tshuab tsis tshua muaj siab casting tshuab yog ntau ntse thiab automated, thiab phau ntawv ua hauj lwm tsuas yog yuav tsum tau ua hauj lwm pab. Txawm li cas los xij, rau hom kev tswj hwm zoo heev, thaum lub sij hawm casting txheej txheem, phau ntawv ua haujlwm tuaj yeem saib xyuas ib kab los ntawm ib tus neeg thiab tsuas yog ua lub luag haujlwm ntawm kev soj ntsuam xyuas. Yog li ntawd, lub unmanned unit ntawm low-pressure casting yog qhia, thiab industrial robots ua tiav tag nrho cov pab pawg neeg ua hauj lwm.

Muaj ob hom kev siv ntawm unmanned low-pressure casting units:

(1) Rau castings nrog ntau yam khoom specifications, yooj yim casting, thiab loj batch, ib tug neeg hlau muaj peev xwm tswj tau ob tug low-pressure casting tshuab. Kev lag luam neeg hlau ua tiav tag nrho cov haujlwm xws li tshem tawm cov khoom, lim qhov chaw, cov lej hlau, thiab tshem tawm tis, yog li paub txog qhov tsis muaj neeg siv khoom. Vim muaj qhov sib txawv spatial layouts, industrial robots yuav dai upside down los yog pem teb-sawv.

(2) Rau castings nrog ib qho khoom tshwj xeeb, yuav tsum tau muab cov ntawv tso rau ntawm cov xuab zeb cores, thiab cov khoom loj, cov neeg hlau ncaj qha coj cov khoom los ntawm lub tshuab tsis tshua muaj siab, txias rau lawv, lossis muab tso rau hauv lub tshuab drilling thiab hloov mus rau cov txheej txheem tom ntej.

3) Rau castings uas yuav tsum tau xuab zeb cores, yog hais tias cov xuab zeb core qauv yog yooj yim thiab cov xuab zeb cores yog ib leeg, industrial robots kuj tseem siv tau los ntxiv cov haujlwm ntawm kev noj thiab muab cov xuab zeb cores. Kev tuav ntawm cov xuab zeb cores yuav tsum tau nkag mus rau hauv pwm kab noj hniav, thiab qhov kub hauv pwm yog siab heev. Qee cov xuab zeb cores hnyav thiab xav tau kev pab ntawm ntau tus neeg ua kom tiav. Yog tias lub sijhawm ua haujlwm ntev dhau lawm, pwm kub yuav poob, cuam tshuam rau qhov zoo ntawm casting. Yog li ntawd, nws yog ib qho tsim nyog yuav tsum siv cov neeg hlau ua lag luam los hloov cov xuab zeb core tso.

Tam sim no, kev ua haujlwm pem hauv ntej ntawm kev ua haujlwm siab casting, xws li nchuav thiab txau pwm, tau ua tiav los ntawm cov txheej txheem siab heev, tab sis kev tshem tawm cov castings thiab ntxuav cov khoom taub hau feem ntau yog ua manually. Vim muaj cov yam ntxwv xws li qhov kub thiab qhov hnyav, kev ua haujlwm ntawm kev ua haujlwm tsawg, uas nyob rau hauv lem txwv lub peev xwm ntau lawm ntawm lub tshuab casting. Kev lag luam neeg hlau tsis yog tsuas yog ua tau zoo hauv kev tshem tawm cov khoom, tab sis kuj ua tiav ib txhij ua tiav kev txiav cov khoom siv lub taub hau thiab cov hnab slag, ntxuav cov fins ya, thiab lwm yam, ua kom tag nrho kev siv cov neeg hlau ua lag luam kom ua tiav cov nyiaj rov qab los ntawm kev nqis peev.

Lub sij hawm xa tuaj: Plaub Hlis-08-2024