Kuv ntseeg tias txhua tus tau hnovtus neeg hlau. Nws feem ntau qhia tau hais tias nws qhov kev ua tau zoo hauv cov yeeb yaj kiab, lossis yog Iron Man tus txiv neej sab xis, los yog ua haujlwm ntau yam cuab yeej hauv cov cuab yeej siv tshuab precision. Cov kev xav txog kev nthuav qhia no muab peb qhov kev xav ua ntej thiab xav paub txogtus neeg hlau. Yog li dab tsi yog ib qho kev lag luam raug neeg hlau?

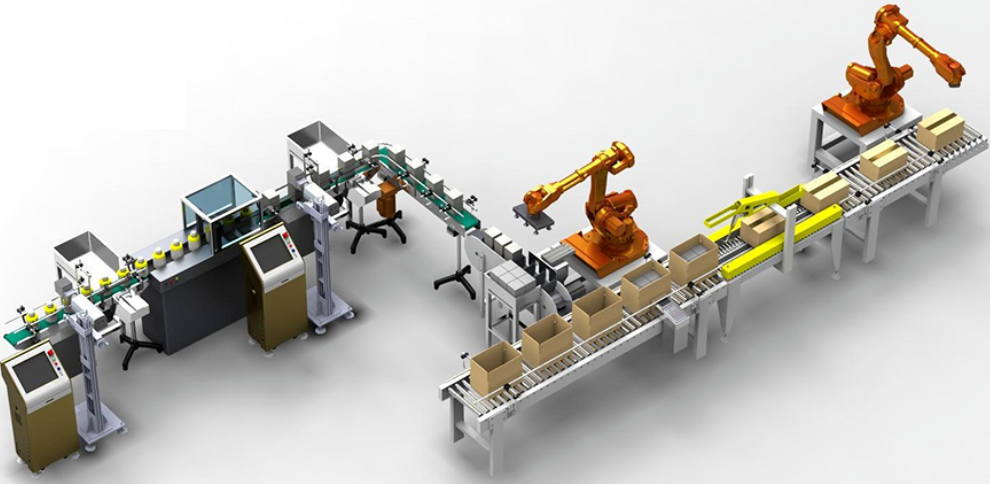

Anindustrial manufacturing neeg hlauyog cov cuab yeej siv tshuab uas tuaj yeem ua haujlwm tau zoo. Nws tuaj yeem ua raws li qee qhov kev txav ntawm tib neeg caj npab thiab ua haujlwm xws li kev tuav cov khoom, kev ua haujlwm, thiab cov khoom sib dhos hauv ib puag ncig kev tsim khoom. Piv txwv li, nyob rau hauv ib lub rooj cob qhia kev tsim tsheb, tus neeg hlau tuaj yeem muab cov khoom siv hauv tsheb kom raug thiab nruab rau hauv txoj haujlwm. Industrial manufacturing robots feem ntau yog siv los ntawm cov khoom siv tsav tsheb xws li lub cev muaj zog, lub tog raj kheej, thiab lub tog raj kheej hydraulic. Cov cuab yeej tsav no txav cov pob qij txha ntawm cov neeg hlau raws li cov lus txib ntawm kev tswj hwm. Lub kaw lus tswj feem ntau yog tsim los ntawm tus tswj, lub sensor, thiab lub programming ntaus ntawv. Tus maub los yog "lub hlwb" ntawm tus neeg hlau, uas tau txais thiab ua ntau yam lus qhia thiab cov cim. Lub sensor yog siv los txheeb xyuas txoj haujlwm, nrawm, quab yuam, thiab lwm yam ntaub ntawv xwm txheej ntawm tus neeg hlau. Piv txwv li, thaum lub sij hawm sib dhos txheej txheem, lub zog sensor yog siv los tswj lub zog sib dhos kom tsis txhob muaj kev puas tsuaj rau cov khoom. Cov cuab yeej programming tuaj yeem yog tus kws qhia ntawv lossis khoos phis tawj programming software, thiab cov lus tsa suab, kev ua ntu zus thiab kev ua haujlwm ntawm tus tswj hwm tuaj yeem teeb tsa los ntawm programming. Piv txwv li, hauv kev ua haujlwm welding, txoj kev txav mus los thiab vuam tsis zoo ntawm lub tshuab vuam lub taub hau, xws li vuam ceev, qhov loj me tam sim no, thiab lwm yam, tuaj yeem tsim los ntawm kev ua haujlwm.

Functional nta:

High precision: Nws tuaj yeem ua tau raws txoj haujlwm thiab ua haujlwm, thiab qhov yuam kev tuaj yeem tswj tau ntawm millimeter lossis txawm micron qib. Piv txwv li, nyob rau hauv kev tsim cov cuab yeej precision, lub manipulator tuaj yeem sib sau ua ke thiab txheej txheem.

Kev kub ceev: Nws tuaj yeem ua tiav cov kev ua rov ua dua sai sai thiab txhim kho kev tsim khoom. Piv txwv li, nyob rau hauv ib tug automated ntim cov kab ntau lawm, tus manipulator tuaj yeem ceev cov khoom thiab muab tso rau hauv ntim ntim.

Kev ntseeg siab: Nws tuaj yeem ua haujlwm ruaj khov rau lub sijhawm ntev thiab txo qhov ua yuam kev los ntawm yam xws li qaug zog thiab kev xav. Piv nrog rau kev siv tes ua haujlwm, hauv qee qhov chaw ua haujlwm hnyav, xws li kub, tshuaj lom neeg, thiab kev siv siab, tus neeg siv khoom tuaj yeem ua haujlwm tsis tu ncua.

Flexibility: Nws cov haujlwm ua haujlwm thiab cov qauv txav tuaj yeem hloov pauv los ntawm kev ua haujlwm kom haum rau cov kev xav tau sib txawv. Piv txwv li, tib lub manipulator tuaj yeem ua cov khoom siv ceev ceev hauv lub caij nyoog ntau lawm thiab kev sib dhos zoo ntawm cov khoom hauv lub caij tawm.

Dab tsi yog daim ntawv thov ntawm industrial manufacturing manipulators?

Automobile Manufacturing Industry

Kev tuav thiab sib dhos: Ntawm cov tsheb tsim khoom, cov neeg hlau tuaj yeem nqa cov khoom loj xws li cov cav thiab cov khoom xa tuaj thiab sib dhos kom raug rau lub chassis ntawm lub tsheb. Piv txwv li, 6-axis neeg hlau tuaj yeem nruab lub rooj zaum hauv tsheb mus rau ib qho chaw ntawm lub tsheb lub cev uas muaj qhov siab tshaj plaws, thiab nws qhov chaw qhov tseeb tuaj yeem ncav cuag ± 0.1 hli, txhim kho kev sib dhos ua tau zoo thiab zoo. Vuam Kev Ua Haujlwm: Lub vuam ua haujlwm ntawm lub tsheb lub cev yuav tsum tau ua haujlwm siab thiab ceev. Cov neeg hlau tuaj yeem welding ntau qhov chaw ntawm lub cev ua ke siv qhov chaw vuam lossis arc vuam tshuab raws li txoj hauv kev ua ntej. Piv txwv li, cov neeg tsim khoom lag luam tuaj yeem ua tiav qhov vuam ntawm lub tsheb qhov rooj hauv 1-2 feeb.

Kev lag luam hluav taws xob thiab hluav taws xob

Circuit Board Manufacturing: Thaum lub sij hawm tsim cov khoom siv hluav taws xob, cov neeg hlau tuaj yeem txuas cov khoom siv hluav taws xob. Nws tuaj yeem txhim kho cov khoom me me xws li cov resistors thiab capacitors ntawm Circuit Court boards ntawm qhov ceev ntawm ob peb lossis txawm kaum ob ntawm cov khoom ib ob. Cov khoom sib dhos: Rau kev sib dhos ntawm cov khoom siv hluav taws xob, xws li xov tooj ntawm tes thiab khoos phis tawj, cov neeg hlau tuaj yeem ua tiav cov haujlwm xws li lub plhaub sib dhos thiab kev teeb tsa. Siv lub xov tooj ntawm tes sib dhos ua piv txwv, tus neeg hlau tuaj yeem txhim kho cov khoom sib xws xws li cov ntxaij vab tshaus thiab cov koob yees duab rau hauv lub cev ntawm lub xov tooj ntawm tes, kom ntseeg tau qhov sib xws thiab zoo ntawm cov khoom sib dhos.

Mechanical processing kev lag luam

Kev thauj khoom thiab kev thauj mus los: Hauv pem hauv ntej ntawm CNC tshuab cuab yeej, tshuab stamping thiab lwm yam khoom siv, tus neeg hlau tuaj yeem ua haujlwm ntawm kev thauj khoom thiab tshem tawm. Nws tuaj yeem rub cov khoom dawb los ntawm lub silo thiab xa mus rau qhov chaw ua haujlwm ntawm cov cuab yeej ua haujlwm, thiab tom qab ntawd tshem tawm cov khoom tiav lossis cov khoom tiav ib nrab tom qab ua tiav. Piv txwv li, thaum CNC tshuab dhos txheej txheem ncej ncej, cov neeg hlau tuaj yeem ua tiav cov haujlwm thauj khoom thiab tshem tawm txhua 30-40 vib nas this, uas txhim kho kev siv tus nqi ntawm lub tshuab cuab yeej. Kev pab ua ib feem: Hauv kev ua haujlwm ntawm qee qhov nyuaj, tus neeg hlau tuaj yeem pab hauv qhov flipping thiab qhov chaw ntawm qhov chaw. Piv txwv li, thaum ua cov pwm nyuaj nrog ntau lub ntsej muag, cov neeg hlau tuaj yeem tig cov pwm mus rau lub kaum sab xis tsim nyog tom qab ib txheej txheem tiav los npaj rau cov txheej txheem tom ntej, yog li txhim kho qhov ua tau zoo thiab raug ntawm kev ua haujlwm.

Kev lag luam zaub mov thiab dej haus

Kev ntim khoom: Hauv kev ntim khoom sib txuas ntawm cov khoom noj thiab dej haus, tus neeg hlau tuaj yeem tuav cov khoom thiab muab tso rau hauv lub thawv ntim khoom lossis lub hnab ntim khoom. Piv txwv li, nyob rau hauv ib lub khob haus dej ntau lawm kab, tus neeg hlau tuaj yeem lob thiab ntim 60-80 fwj ntawm cov dej haus ib feeb, thiab tuaj yeem ua kom zoo thiab ua raws li kev ntim khoom.

Kev ua haujlwm sorting: Rau kev txheeb xyuas zaub mov, xws li kev txheeb xyuas thiab txheeb xyuas cov txiv hmab txiv ntoo thiab zaub, tus neeg hlau tuaj yeem txheeb xyuas raws li qhov loj, qhov hnyav, xim thiab lwm yam khoom ntawm cov khoom. Nyob rau hauv cov txheej txheem sorting tom qab cov txiv hmab txiv ntoo raug xaiv, tus neeg hlau tuaj yeem txheeb xyuas cov txiv hmab txiv ntoo ntawm cov qib zoo sib txawv thiab muab tso rau hauv ntau qhov chaw, uas txhim kho cov kev sib cais thiab cov khoom zoo.

Logistics thiab warehousing kev lag luam

Cargo tuav thiab palletizing: Hauv warehouse, tus neeg hlau tuaj yeem nqa cov khoom ntawm ntau yam duab thiab qhov hnyav. Nws tuaj yeem nqa cov khoom tawm ntawm lub txee lossis ntim cov khoom ntawm pallets. Piv txwv li, cov logistics loj thiab cov chaw khaws khoom neeg hlau tuaj yeem nqa cov khoom hnyav ob peb tons, thiab tuaj yeem muab cov khoom ntim rau hauv cov khoom sib dhos zoo raws li qee txoj cai, uas txhim kho qhov chaw siv ntawm lub warehouse. Order sorting: Nyob rau hauv ib puag ncig xws li e-lag luam logistics, tus neeg hlau tuaj yeem txheeb cov khoom sib xws los ntawm cov txee ntawm lub tsev rau khoom raws li cov ntaub ntawv xaj. Nws tuaj yeem tshawb xyuas cov ntaub ntawv khoom lag luam sai sai thiab muab cov khoom tso rau ntawm cov khoom siv sib cais, ua kom ceev cov kev txiav txim.

Dab tsi yog qhov tshwj xeeb cuam tshuam ntawm daim ntawv thov kev lag luam kev lag luam manipulators ntawm kev lag luam ntau lawm efficiency?

Txhim kho qhov ceev ntau lawm

Kev ua haujlwm nrawm dua: Cov khoom tsim khoom lag luam tuaj yeem ua haujlwm rov ua haujlwm ntawm kev kub ceev yam tsis muaj qaug zog thiab txo kev ua haujlwm zoo li kev tuav haujlwm. Piv txwv li, nyob rau hauv cov txheej txheem sib dhos ntawm cov khoom siv hluav taws xob, tus neeg siv khoom tuaj yeem ua tiav kaum lossis ntau pua ntawm kev rub thiab teeb tsa ua haujlwm ib feeb, thaum lub sijhawm ua haujlwm ntawm phau ntawv tsuas yog ua tiav ob peb zaug hauv ib feeb. Noj cov xov tooj ntawm tes ua piv txwv, tus naj npawb ntawm cov ntxaij vab tshaus tau teeb tsa hauv ib teev uas siv cov neeg siv khoom tuaj yeem yog 3-5 npaug ntau dua li kev teeb tsa ntawm phau ntawv. Shorten ntau lawm voj voog: Txij li thaum lub manipulator tuaj yeem ua haujlwm 24 teev hauv ib hnub (nrog kev saib xyuas kom zoo) thiab muaj kev hloov pauv ceev ntawm cov txheej txheem, nws ua rau lub voj voog ntau lawm ntawm cov khoom. Piv txwv li, hauv kev tsim tsheb, kev ua haujlwm zoo ntawm cov khoom siv hauv lub cev vuam thiab cov khoom sib txuas tau txo cov sij hawm sib dhos ntawm lub tsheb los ntawm kaum ob teev mus rau ntau tshaj kaum teev tam sim no.

Txhim kho cov khoom zoo

Kev ua haujlwm siab-precision: Kev ua haujlwm raug ntawm tus neeg siv khoom yog ntau dua li kev ua haujlwm ntawm phau ntawv. Nyob rau hauv precision machining, tus neeg hlau tuaj yeem tswj tau qhov tseeb machining ntawm qhov chaw mus rau qib micron, uas yog qhov nyuaj rau kev ua tiav nrog kev tuav haujlwm. Piv txwv li, hauv kev tsim cov khoom saib, cov neeg hlau tuaj yeem ua tiav qhov kev txiav thiab sib tsoo ntawm cov khoom me me xws li cov iav, kom ntseeg tau qhov tseeb qhov tseeb thiab qhov chaw tiav ntawm cov khoom, yog li txhim kho tag nrho cov khoom zoo.

Kev ruaj ntseg zoo: Nws qhov kev ua tau zoo sib xws yog qhov zoo, thiab cov khoom lag luam zoo yuav tsis hloov pauv vim yog yam xws li kev xav thiab kev qaug zog. Nyob rau hauv cov txheej txheem ntawm kev ntim tshuaj, tus neeg hlau tuaj yeem tswj xyuas qhov ntau npaum li cas ntawm cov tshuaj thiab kev sib khi ntawm lub pob, thiab qhov zoo ntawm txhua lub pob tuaj yeem ua kom zoo ib yam, txo tus nqi tsis zoo. Piv txwv li, hauv kev ntim khoom noj, tom qab siv cov neeg hlau, cov khoom lag luam poob qis los ntawm kev ntim khoom tsis tsim nyog tuaj yeem txo los ntawm 5% - 10% hauv kev tuav haujlwm mus rau 1% - 3%.

Optimize ntau lawm txheej txheem

Automated txheej txheem kev koom ua ke: Cov neeg hlau tuaj yeem sib txuas nrog lwm cov khoom siv automated (xws li cov kab ntau lawm, tsis siv neeg warehousing systems, thiab lwm yam) kom optimize tag nrho cov txheej txheem ntau lawm. Ntawm cov kab ntau lawm ntawm cov khoom siv hluav taws xob, cov neeg hlau tuaj yeem sib koom ua ke ntawm kev tsim khoom, kev sim thiab kev sib dhos ntawm cov rooj sib tham hauv Circuit Court kom ua tiav cov khoom siv txuas ntxiv los ntawm cov khoom siv raw mus rau cov khoom tiav. Piv txwv li, nyob rau hauv ib tug ua tiav lub computer motherboard ntau lawm Rhiav, tus neeg hlau tuaj yeem tswj hwm ntau yam khoom siv los ua kom tiav cov txheej txheem los ntawm kev tsim cov ntawv luam tawm Circuit Board rau chip installation thiab vuam, txo lub sijhawm tos thiab tib neeg kev cuam tshuam hauv kev sib txuas nruab nrab. Kev hloov kho ua haujlwm yooj yim: Cov neeg hlau ua haujlwm thiab kev txiav txim siab ua haujlwm tuaj yeem hloov kho tau yooj yim los ntawm kev ua haujlwm kom haum rau cov kev xav tau ntau lawm thiab cov khoom hloov pauv. Hauv kev tsim cov khaub ncaws, thaum cov style hloov, tsuas yog cov neeg hlau qhov kev pab cuam yuav tsum tau hloov kho kom haum rau kev txiav, xaws kev pab thiab lwm yam dej num ntawm cov qauv tshiab ntawm cov khaub ncaws, uas txhim kho qhov yooj thiab adaptability ntawm cov txheej txheem ntau lawm.

Txo cov nqi tsim khoom

Txo cov nqi zog: Txawm hais tias thawj zaug peev ntawm cov neeg hlau yog siab, nyob rau hauv lub sij hawm ntev, nws muaj peev xwm hloov tau ib tug loj npaum li cas ntawm cov neeg ua hauj lwm phau ntawv thiab txo lub tuam txhab cov nqi zog. Piv txwv li, lub tuam txhab tsim khoom ua si siv zog tuaj yeem txo 50% -70% ntawm cov neeg ua haujlwm sib dhos tom qab qhia cov neeg hlau rau kev sib dhos ntawm qee qhov chaw, yog li txuag nyiaj ntau hauv cov nqi zog. Txo cov khoom seem thiab cov khoom poob: Vim tias cov neeg hlau tuaj yeem ua haujlwm tau zoo, nws txo cov khoom seem los ntawm kev ua haujlwm yuam kev, thiab tseem txo cov khoom poob. Thaum lub sij hawm tus txheej txheem ntawm kev khaws thiab txiav cov khoom txhaj tshuaj molded, tus neeg hlau tuaj yeem ua tiav cov khoom kom tsis txhob muaj cov khoom puas tsuaj thiab cov khoom pov tseg ntau dhau, txo cov seem seem los ntawm 30% - 50% thiab cov khoom poob los ntawm 20% - 40%.

Post lub sij hawm: Jan-21-2025