1. Lub hauv paus chiv keeb ntawm Industrial Robots Lub invention ntawm industrial robots tuaj yeem taug qab rov qab rau xyoo 1954, thaum George Devol tau thov rau patent ntawm programmable qhov chaw hloov dua siab tshiab. Tom qab koom tes nrog Joseph Engelberger, lub ntiaj teb thawj lub tuam txhab neeg hlau Unimation tau tsim, thiab thawj cov neeg hlau tau muab tso rau hauv General Motors cov kab ntau lawm hauv xyoo 1961, feem ntau yog rub cov khoom tawm ntawm lub tshuab tuag-casting. Feem ntau hydraulically powered universal manipulators (Unimates) tau muag nyob rau hauv lub xyoo tom ntej, siv rau lub cev manipulation thiab chaw vuam. Ob daim ntawv thov tau ua tiav, qhia tias cov neeg hlau tuaj yeem ua haujlwm tau ntseeg tau thiab lav cov qauv zoo. Tsis ntev, ntau lwm lub tuam txhab pib tsim thiab tsim cov neeg hlau ua lag luam. Ib qho kev lag luam uas tau tsav los ntawm kev tsim kho tshiab tau yug los. Txawm li cas los xij, nws tau siv ntau xyoo rau qhov kev lag luam no kom tau txais txiaj ntsig tiag tiag.

2. Stanford Caj Npab: Ib qho Kev Txhaum Loj hauv Robotics Lub hauv paus "Stanford Arm" tau tsim los ntawm Victor Scheinman hauv xyoo 1969 ua tus qauv ntawm txoj haujlwm tshawb fawb. Nws yog ib tug tub ntxhais kawm engineering hauv Department of Mechanical Engineering thiab ua haujlwm ntawm Stanford Artificial Intelligence Laboratory. Lub "Stanford Arm" muaj 6 qib ntawm kev ywj pheej, thiab cov khoom siv hluav taws xob tag nrho yog tswj los ntawm lub khoos phis tawj txheem, cov cuab yeej digital hu ua PDP-6. Qhov no tsis yog-anthropomorphic kinematic qauv muaj ib tug prism thiab tsib revolute pob qij txha, uas ua rau nws yooj yim los daws cov neeg hlau kinematic equations, yog li ua kom lub zog ntawm lub computer. Tus tsav module muaj DC lub cev muaj zog, kev sib haum xeeb tsav thiab lub spur iav reducer, potentiometer thiab tachometer rau txoj hauj lwm thiab kev tawm tswv yim ceev. Tom qab tsim neeg hlau tau cuam tshuam los ntawm Scheinman lub tswv yim.

3. Yug ntawm lub tshuab hluav taws xob muaj hluav taws xob tag nrho Hauv xyoo 1973, ASEA (tam sim no ABB) tau tsim lub ntiaj teb thawj microcomputer-tswj, tag nrho cov hluav taws xob muaj hluav taws xob IRB-6. Nws tuaj yeem ua txoj hauv kev txuas mus ntxiv, uas yog qhov yuav tsum tau ua ua ntej rau arc vuam thiab ua haujlwm. Nws tau tshaj tawm tias qhov kev tsim qauv no tau ua pov thawj tias muaj zog heev thiab cov neeg hlau muaj lub neej ua haujlwm txog li 20 xyoo. Hauv xyoo 1970, cov neeg hlau tau nthuav dav mus rau kev lag luam tsheb, feem ntau yog siv rau vuam thiab thauj khoom thiab thauj khoom.

4. Revolutionary Design of SCARA Robots Hauv xyoo 1978, Selectively Compliant Assembly Robot (SCARA) tau tsim los ntawm Hiroshi Makino ntawm University of Yamanashi, Nyiv. Qhov no landmark plaub-axis tus nqi qis tsim tau zoo haum rau cov kev xav tau ntawm cov khoom me me los ua ke, raws li cov qauv kinematic tau tso cai nrawm thiab ua raws li caj npab. Kev sib dhos yooj yim raws li SCARA cov neeg hlau nrog cov khoom tsim tau zoo sib xws tau txhawb nqa kev loj hlob ntawm cov khoom siv hluav taws xob thiab cov neeg siv khoom thoob ntiaj teb.

5. Kev txhim kho ntawm Kev Nyuaj Siab thiab Kev Ua Si Robots Cov kev xav tau ntawm cov neeg hlau ceev thiab loj tau ua rau cov qauv tshiab kinematic thiab kis tau tus mob. Txij thaum ntxov, txo qhov loj thiab inertia ntawm tus neeg hlau qauv yog lub hom phiaj tseem ceeb ntawm kev tshawb fawb. Qhov hnyav piv ntawm 1: 1 rau tib neeg txhais tes tau suav tias yog qhov ntsuas qhov kawg. Xyoo 2006, lub hom phiaj no tau ua tiav los ntawm cov neeg hlau sib sib zog nqus los ntawm KUKA. Nws yog ib tug compact xya-degree-ntawm-kev ywj pheej neeg hlau caj npab nrog advanced quab yuam tswj muaj peev xwm. Lwm txoj hauv kev kom ua tiav lub hom phiaj ntawm lub teeb yuag thiab cov qauv nruj tau tshawb nrhiav thiab nrhiav txij li xyoo 1980s, uas yog kev txhim kho cov cuab yeej siv tshuab ua ke. Cov tshuab no txuas lawv qhov kawg effectors rau lub tshuab puag module ntawm 3 mus rau 6 parallel brackets. Cov no hu ua parallel robots yog qhov tsim nyog rau kev kub ceev (xws li kev tuav), siab precision (xws li kev ua haujlwm) lossis tuav cov khoom siab. Txawm li cas los xij, lawv qhov chaw ua haujlwm me dua li qhov zoo sib xws serial lossis qhib-loop robots.

6. Cartesian robots thiab ob txhais tes robots Tam sim no, Cartesian neeg hlau tseem zoo tagnrho rau cov ntawv thov uas xav tau ib puag ncig kev ua haujlwm dav. Ntxiv nrog rau cov qauv tsim siv peb-dimensional orthogonal translation axes, Gudel tau npaj ib qho kev sib tw thav duab hauv xyoo 1998. Lub tswv yim no tso cai rau ib lossis ntau dua neeg hlau caj npab taug qab thiab ncig hauv lub kaw lus hloov chaw. Nyob rau hauv txoj kev no, tus neeg hlau qhov chaw ua haujlwm tuaj yeem txhim kho nrog kev kub ceev thiab qhov tseeb. Qhov no tej zaum yuav muaj txiaj ntsig tshwj xeeb hauv kev xa khoom thiab kev tsim tshuab.Qhov kev ua haujlwm zoo ntawm ob txhais tes yog qhov tseem ceeb rau kev ua haujlwm nyuaj, kev ua haujlwm ib txhij thiab kev thauj khoom ntawm cov khoom loj. Thawj cov khoom lag luam muaj synchronous ob txhais tes neeg hlau tau qhia los ntawm Motoman hauv 2005. Raws li ob txhais tes neeg hlau uas ua raws li kev ncav cuag thiab dexterity ntawm tib neeg caj npab, nws tuaj yeem muab tso rau hauv qhov chaw uas cov neeg ua haujlwm yav dhau los ua haujlwm. Yog li ntawd, cov nqi peev yuav raug txo. Nws nta 13 axes ntawm kev txav: 6 nyob rau hauv txhua txhais tes, ntxiv rau ib qho axis rau kev sib hloov yooj yim.

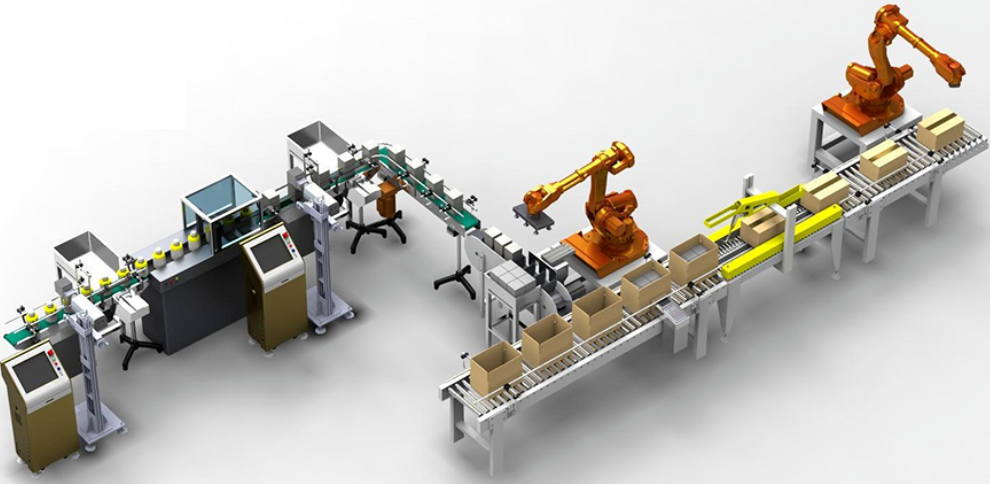

7. Mobile Robots (AGVs) thiab Flexible Manufacturing Systems Tib lub sijhawm, muaj cov neeg hlau tsis siv neeg coj tsheb (AGVs) tshwm sim. Cov neeg hlau txawb no tuaj yeem txav mus los ntawm qhov chaw ua haujlwm lossis siv rau kev thauj khoom ntawm cov khoom siv taw tes. Nyob rau hauv lub tswv yim ntawm automated saj zawg zog manufacturing systems (FMS), AGVs tau dhau los ua ib feem tseem ceeb ntawm txoj kev yooj.Originally, AGVs cia siab rau pre-npaj platforms, xws li embedded xov hlau los yog hlau nplaum, rau kev taw qhia navigation. Meanwhile, dawb-navigating AGVs yog siv nyob rau hauv loj-scale manufacturing thiab logistics. Feem ntau lawv cov navigation yog raws li laser scanners, uas muab ib daim ntawv qhia tseeb 2D ntawm qhov chaw tam sim no rau autonomous positioning thiab obstacle avoidance.Los ntawm qhov pib, kev sib xyaw ntawm AGVs thiab neeg hlau caj npab tau txiav txim siab tias yuav tuaj yeem thauj khoom thiab tshem tawm cov cuab yeej siv tshuab. Tab sis qhov tseeb, cov caj npab neeg hlau no muaj kev lag luam thiab tus nqi zoo tsuas yog nyob rau qee lub sijhawm tshwj xeeb, xws li thauj khoom thiab thauj khoom hauv kev lag luam semiconductor.

8. Xya txoj kev loj hlob ntawm kev lag luam robots Raws li xyoo 2007, evolution ntawm industrial robots tuaj yeem raug cim los ntawm cov ncauj lus tseem ceeb hauv qab no: 1. Kev txo nqi thiab kev txhim kho kev ua haujlwm - Qhov nruab nrab nqi ntawm cov neeg hlau tau nqis mus rau 1/3 ntawm tus nqi qub ntawm cov neeg hlau sib npaug hauv xyoo 1990, uas txhais tau hais tias cov khoom siv hluav taws xob pheej yig dua thaum lub sij hawm ua haujlwm zoo tib yam. (xws li kev ceev, lub peev xwm thauj khoom, lub sijhawm nruab nrab ntawm kev ua tsis tiav MTBF) tau txhim kho tau zoo. 2. Kev koom ua ke ntawm PC thev naus laus zis thiab IT Cheebtsam - Tus Kheej lub computer (PC) thev naus laus zis, cov neeg siv khoom qib software thiab cov khoom npaj tau los ntawm kev lag luam IT tau txhim kho tus nqi-zoo ntawm cov neeg hlau.- Tam sim no, feem ntau cov tuam txhab koom ua ke PC-based processors nrog rau cov programming, kev sib txuas lus thiab simulation rau hauv cov maub los, thiab siv cov khoom lag luam siab. 3. Ntau tus neeg hlau sib koom ua ke tswj - Ntau tus neeg hlau tuaj yeem ua haujlwm thiab sib koom ua ke thiab sib koom ua ke hauv lub sijhawm tiag tiag los ntawm tus tswj hwm, uas tso cai rau cov neeg hlau ua haujlwm tau zoo ua ke hauv ib qho chaw ua haujlwm. 4. Kev siv lub zeem muag dav dav – Lub zeem muag systems rau kev paub txog cov khoom, qhov chaw thiab kev tswj kom zoo tau nce los ua ib feem ntawm cov neeg hlau tswj.5. Kev sib txuas lus thiab kev tswj chaw taws teeb - Cov neeg hlau txuas nrog lub network ntawm fieldbus lossis Ethernet kom tswj tau zoo dua, teeb tsa thiab kev saib xyuas.6. Cov qauv kev lag luam tshiab - Cov phiaj xwm nyiaj txiag tshiab tso cai rau cov neeg siv kawg tuaj yeem xauj cov neeg hlau lossis muaj lub tuam txhab kev tshaj lij lossis txawm tias tus neeg muab kev pabcuam neeg hlau ua haujlwm rau cov neeg hlau, uas tuaj yeem txo cov kev pheej hmoo peev thiab txuag nyiaj.7. Nrov nrov ntawm kev cob qhia thiab kev kawm - Kev cob qhia thiab kev kawm tau dhau los ua cov kev pabcuam tseem ceeb rau ntau tus neeg siv kawg kom paub txog cov neeg hlau. - Cov ntaub ntawv xov xwm tshaj lij thiab cov chav kawm yog tsim los qhia cov kws tshaj lij thiab cov neeg ua haujlwm kom lawv npaj tau zoo, kev pab cuam, ua haujlwm thiab tswj cov neeg hlau.

,

Lub sij hawm xa tuaj: Plaub Hlis-15-2025